+ 2” Bar Capacity with 6,000 RPM Spindle

+ Full “C” Axis on Main Spindle and Sub Spindle

+ Full “Y” Axis on Main Spindle and Sub Spindle

+ 33 Total Tool Positions with 13 Live Tools

+ Simultaneous Main and Sub-Spindle Machining

+ Parts Catcher and Chip Conveyor Standard

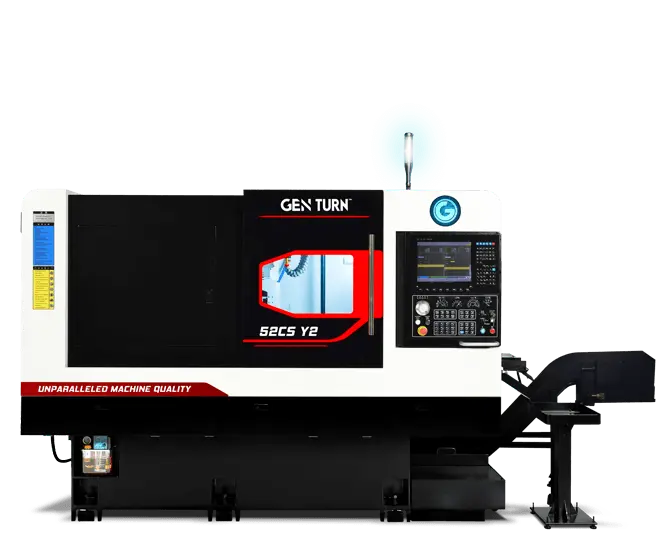

MACHINE SPECIFICATIONS: GEN TURN 52CS Y2

GEN TURN Super 210T

Advanced Multi-Tasking CNC Control

Main Spindle

Maximum RPM / spindle bearing 6,000 RPM

Spindle Motor 10-HP (7.5 kw)

Collet Nose / Spindle Bore Traub TRB-52 / 51 mm (uses TRB-52 collet)

Maximum Barstock Diameter 2” (51 mm)

Maximum Cut Length 14”

Spindle Center Height 43.3” (1,100 mm)

Sub Spindle

Sub spindle RPM / spindle bearing 6,000 RPM / 4-bearing Quad-Duplex pair configuration Sub spindle Motor 6-HP (4.4 kw)

Collet Nose / Spindle Bore Traub TRB-42 / 43 mm (uses TRB-42 collet)

External Air Blast nozzle Included for both main & sub spindle

Finished Parts Ejector & air blast (Max 7.5” part front eject) Included for sub spindle

Axes Specifications

X1-axis Travel 8.66” (220 mm)

Y1-axis Travel (true Y-axis, not compound Y) 24.41” (620 mm)

Z1-axis Travel 16.0” (406 mm)

X2-axis Travel 14.9” (380 mm)

Y2-axis Travel (true Y-axis, not compound Y) 5.11” (130 mm)

Z2-axis Travel 18.1” (460 mm) Rapid Traverse Rate – X1, X2, Y1, Z1, Z2 1,181 IPM (30 m/min) Rapid Traverse Rate – Y2 196 IPM (5 m/min)

Axis Drive Servo Horsepower: X1/Y1/Z1 1-3/4 / 1-3/4 / 1-1/8 HP (1.3 kw /1.3 kw / .85 kw)

Axis Drive Servo Horsepower: X2/Y2/Z2 1-1/8 / 1.0 / 1-1/8 HP (.85 kw / .75 kw / .85 kw)

Minimum input unit 0.0001” (0.001 mm = 40 millionths inch)

Tooling

33-Tool Positions Standard All live tools are gear driven w/ ø42mm bearings – no belts!

Main Spindle Cross Slide Radial live tools 6-ER-20 cross slide live tools, 4,000 rpm, 2.0 HP (1.5 kw)

Main Spindle Front Slide Axial live tools 3-ER-20 front slide live tools, 4,000 rpm, 1.0 HP (0.75 kw)

Main Spindle OD Turning Tool Positions 6 (5x 5/8” + 1x 3/4”) (5x16 mm) + (1x20 mm)

Main Spindle ID Turning Tool Positions 5 ID Tool Bores (25 mm)

Sub Spindle ID Turning Tool Positions 5 ID Tool Bores (25 mm) (back of main tool bores)

Sub Spindle ID Turning Tool Positions 4 ID Tool Bores (Static holders in sub spindle tool block)

Sub Spindle Back Slide Axial live tools 4-ER-20 (can add 4 more) 4,000 rpm, 4.0 HP (3kw)

(1 radial live tool can be substituted on Sub Spindle tool block)

Machine

Machine Weight 13,880 lbs (6,300 kgs)

Coolant Pump Dual 50psi 1-HP Coolant Pumps for main and Sub Spindle

Coolant Tank Capacity 63-gallon coolant tank, with coolant flow confirmation sensor

Lubrication distribution Way lube distributed at 3-6 cc / 15-minute cycle Hydraulic System – power / capacity 1-HP / 12-gallons (0.75 kw / 46 L)

Machine Power Requirements 220 vac ±5%, 35 kva, 3-phase, 60 Hz, 92 amps

Air Requirements 85-PSI at 10-CFM for parts catcher, parts ejector, & air blast

All specifications are subject to change without prior notice.

GEN TURN - 52CS Y2 Pricing

All 52CS Y2 machines come with all standard accessories listed below:

Parts catcher and finished parts fabric conveyor with parts catcher basket

A-52 “Dead-Length” Collet System for main and A-42 “Dead- Length” for the sub spindle

Automatic belt-style chip conveyor and wheeled chip cart

Sub-spindle programmable air blast, oil flush and finished parts ejector

Automatic Barfeed Interface, Barfeed Connector, Toolbox & Tool Kit

Automatic Power off controller & Air-conditioned electrical cabinet

Dual ¾-hp 50psi Coolant Pumps, with double coolant filtration and a coolant flow monitor

ER-20 Collet Extensions – Total of 6 single-end ER-20 collet extensions for 25mm tool bores

13 live-tool ER-20 gear-driven collet spindles

GEN TURN 52CS Y2 8-Axis CNC LATHE SPECIAL VALUE PACKAGE PRICE: $174,990.00

• Touch screen control with 36- part program storage

• Swiss synchronization kit with telescopic nose

• Dual anti-vibration device – rollers and bushing device

• Remnant retraction

• Air- knife with flow control included

• Channel set, pusher, rotating tip

• 1-Collet and 1-bushing block included

GEN TURN 52CS Y2 8-Axis CNC LATHE - GRAND PACKAGE GRAND PACKAGE PRICE: $224,990.00

With Edge Patriot 551 12’ Automatic Barloader Installed at your facility

MP-Systems 4-Port 1,000 PSI High Pressure system and Mistbuster Mist System Installed

GEN TURN 52CS Y2 Machine Options:

Factory machine installation: “Peace-of-Mind Factory Installation” – includes expenses $3,995.00

Factory on-site 3-day machine operation and program training – includes expenses $6,995.00

Long Part Ejection System (42 mm pass thru) $6,995.00

LNS Turbo Chip Conveyor with Fine Chip Filtration (recommended for fine chips) $13,995.00

Cross Milling for Sub Spindle (02-000-0116) $3,995.00

Slotting Saw Unit for Sub Spindle (02-000-0206) $3,995.00

52 mm Adapter for Sub Spindle $1,995.00

Double-ended ER-20 Collet chucks (Static Mill/Drill tools for sub-spindle use) $295.00

Traub 32 Adapter for 52CS Y2 Machine Main and Sub Spindle $1,995.00

Fire Suppression System – with custom installation & interface (17-101-0404) $7,495.00

Please see fire waiver in Expand terms and conditions.

Royal Rota Rack with Deluxe control and standard conveyor $16,955.00

Coolant options: Cutting oil is recommend but the use of water-soluble coolant is also acceptable.

MP-Systems 4-Port 1,000 PSI High Pressure Coolant System 26-101-0405 $13,500.00

MP-System installation $1,000.00

Mistbuster Coolant Filtration Unit (recommended for use with high-pressure $4,990.00

Installation Included

Oil Chiller System (24,000 BTU’s) use when high machining accuracy is required $9,995.00

Installation of Oil Chiller System with connectors and plumbing $495.00

Complete Comprehensive Quote with Features and Descriptions is available upon request.

We use cookies to improve your experience. Privacy Policy.