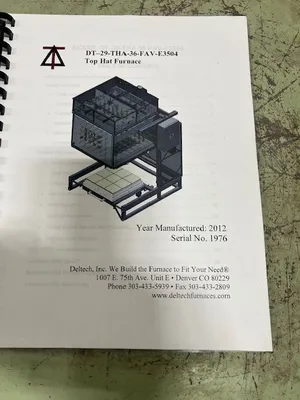

DELTEC DT-29-TAA-36 used heat treatment furnace.

New in 2012.

Max temp 1800°C.

36" x 36" x 36" workspace.

Pneumatic/electric lift, top-hat design, for even heating and convection cooling.

***To the best of our knowledge all details listed below are deemed correct. It is the buyer’s responsibility to confirm all details and we encourage an inspection of the machine(s) and accessories prior to purchase***

Top-hat furnace specifications:

Maximum temperature: Up to 1800°C (around 3272°F).

Workplace dimensions: 36" cubed (36" x 36" x 36") or 914mm cubed.

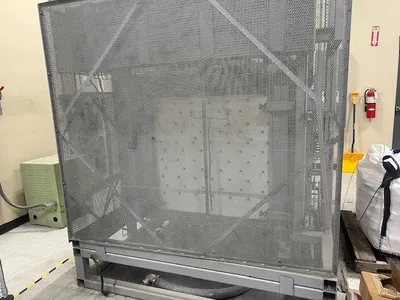

Furnace dimensions: 85" x 84" x 121" (216 cm x 213 cm x 307 cm).

Power requirements:

480V /3PH

75 kW for 1700°C operation.

90 kW for 1800°C operation.

Weight: 4,260 lbs (1,936 kg).

Design: A "top-hat" design, where the furnace body lifts up and down over a fixed base, keeping the load undisturbed.

Actuation: Available with either pneumatic or electric lift systems.

Heating elements: Spaced evenly on all four sides to provide superior temperature uniformity.

Common applications

Top-hat furnaces are ideal for applications where the product being heated must remain stationary. This includes:

*Metallurgy: Heat treatment of metal alloys.

*Crystal growth: Creating uniform thermal conditions for crystal growth experiments.

*Glass manufacturing: For applications involving gradient glass.

*Semiconductor manufacturing: Precision thermal processing of materials

DT-TH-AE-36 36-FAV- E3504 Top Hat Furnace Key Features:

*Deltech top hat furnaces provide superior temperature uniformity. The heating elements are spaced evenly on all four sides.

*The unique pin-and-washer anchoring system in production-size top hats sustains structural integrity via high fires and rapid cycling.

*Furnace linings of the highest quality board and blanket allow rapid heating and cooling.

*Pneumatic (100 psi facility air required) or electric actuation systems are available. The pneumatic system has varying travel speeds, whereas the electric system has a fixed rate of about 88 cm per minute.

*Durable fiberboard exterior panels are offset from the furnace shell to allow for convection cooling, which keeps the furnace skin temperatures safe without cooling fans.

*Forced air and vent flap options are available to help with binder burnout and to increase cooling rates as needed. Designs for “vortex” air flow.

*Atmosphere envelope furnaces for inert gas and up to 5% hydrogen mixture processing.

The 1500, 1600, 1700, and 1800 °C models continuously operate at the maximum rated temperature.

We use cookies to improve your experience. Privacy Policy.